Idiphu eshushu yegalvanizing (ityhubhu yentsimbi) umvelisi

Ukutya → ukukha, ukuvasa → ukunyibilikisa → ukomisa → idiphu eshushu ukuvuthela → ngaphakathi nangaphandle ukuvuthela → ileyibhile yokuqengqeleka, ukuphawula → ukunyanzeliswa → ukuhlola → ukupakisha.

Umsebenzi olayishayo uya kukhangela imeko yezinto:

1. Umphandle wangaphandle wombhobho wensimbi awuyi kubambelela ngeoli (ingakumbi amabala e-oyile afana nepeyinti yokudibanisa ioli ye-asphalt), ngaphandle koko inani elikhulu leemveliso ezingafanelekanga ziya kubangelwa.

2. Umbhobho wensimbi kufuneka ulungiswe emva kokuvelisa ukuphelisa uxinzelelo lwangaphakathi lombhobho wensimbi.

I-3, i-tube ye-tube surface engalinganiyo i-corrosion ayikwazi ukunyanyiswa, ngaphandle koko ininzi ye-hydrochloric acid iya kuchithwa.

- Akukho ukugoba okwenziweyo kuvunyelwe kwinkqubo yokuthutha umbhobho wensimbi.

5. Kwimibhobho yensimbi etshisiweyo eshushu, ayivumelekanga ukuba unamathele amanqaku kwiindonga zangaphakathi nangaphandle zemibhobho yensimbi ukuze kugwenywe ukuvuza.

1. Ukucholwa kombhobho wentsimbi:

I-1) Abasebenzi be-Pickling kufuneka banxibe izinto zokukhusela abasebenzi ngaphambi kokuba basebenze, bahlolisise ngononophelo ukuba kukho indawo yokusebenza engenazithintelo kunye nokuba isilingi silungile, kwaye umsebenzi unokuqhutywa emva kokuqinisekiswa.

2) I-Hydrochloric acid isetyenziswa kakhulu kwi-pickling, kwaye i-hydrochloric acid ilungiswa ngamanzi.Umxholo we-hydrochloric acid ngu-18-20%, ofanelekileyo ngakumbi.

3) Qonda ukuxinwa kwe-asidi, ubushushu kunye netoni yombhobho wokukhetha kwi-tank ngaphambi kokukhetha.

4) Xa uphakamisa umbhobho, izilingi ezibini kufuneka zibe malunga ne-1.3 yeemitha ukusuka ekupheleni, ukuze ugweme ukugoba umbhobho wentsimbi kwaye ubangele ukuvuza kumbhobho we-galvanized; ukuthambeka ngo-15°, ukuze kuthotywe isiphelo sokuma setyhubhu kuqala, ukuze kuthintelwe ukutshiza ngeasidi ekwenzakaleni kwabantu.

5) I-pickling nganye yombhobho wensimbi kufuneka ibe nobunzima beetoni ezi-2 ~ 5 kunye nexesha le-5 ~ 15 imizuzu.

6) I-tube yensimbi kufuneka ingcangcazele rhoqo ngexesha lokukhetha.Kwinkqubo yokunyakaza, ityhubhu yensimbi kufuneka ibekwe kwilitye elithe tye kwitanki ye-asidi, kunye ne-sling kwelinye icala kufuneka iqaliswe ngokuphindaphindiweyo ngamaxesha angama-3, kwaye i-sling kwelinye icala kufuneka iqalwe kwakhona ngamaxesha angama-3. , kwaye emva koko iphakanyiswe emva kokuphindwa kabini;Ukwenyuka kweVibration Iengile ayikho nkulu kuno-15°.

7) Xa itanki ye-asidi ishushu, lungisa umbhobho we-steam ngokuqinileyo ngaphambi kokuvula i-valve ye-steam.

8) Xa i-crane crane ingena okanye ishiya itanki yeasidi, ayisayi kungqubana nodonga lwetanki ukuthintela umonakalo kwitanki yeasidi.

9) Oonobangela abaphambili bokucholwa kweetyhubhu zentsimbi:

(1) umbhobho wensimbi uya kuhlolwa ngokungqongqo xa utyiswa, kwaye umbhobho wensimbi ongafanelekanga awuyi kufakwa kwi-pickling.

(2) Umbhobho wentsimbi awusebenzi kakuhle xa ungcangcazela.

(3) Ixesha lokukhetha elinganeleyo kunye nomxholo we-hydrochloric acid.

10) Ezona zizathu ziphambili zokuchola iityhubhu yentsimbi:

(1) Ubuninzi be-asidi ye-hydroelectric.

(2) Ixesha lokukha lide kakhulu.

11) Emva kokukhetha, khangela ukuba indawo yangaphandle yombhobho wensimbi igudileyo, ingaba kukho isikali sentsimbi eseleyo kunye nokuba umphezulu wombhobho wensimbi ungcoliswe ngumlinganiselo weoli.

2. Ukuhlamba amanzi kwiityhubhu zentsimbi:

1) Ukuhlamba amanzi kombhobho wensimbi kufuneka kuqhutywe kwi-tank yamanzi ecocekileyo ehambayo.Gxumisa wonke umbhobho wentsimbi emanzini xa uhlamba, phumza isilingi sokuchola kwaye ukhuphe kwaye uhambe amaxesha amathathu ukuya kwamane.

2) Emva kokuhlamba, amanzi angaphakathi kwi-tube yensimbi kufuneka alawulwe kwaye aphathwe nge-solvent ngokukhawuleza ukukhusela i-oxidation ye-tube yensimbi.

3) Umxholo wentsimbi kunye netyuwa emanzini okucoca awuyi kudlula umgangatho, kwaye akuyi kubakho ezinye ii-sandries.Iya kugcinwa icocekile kwaye iselubala.

4) Xa ucoca umbhobho, akuvumelekanga ngokungqongqo ukuba abaqhubi banyathele phezu kwetanki yokuchola ukuthintela ukutyibilika okanye ukuwela kwitanki ukulimaza abantu.1.Xa ityhubhu yensimbi ingena kwi-solvent tank, khulula i-sling ukwenzela ukuba ityhubhu yensimbi ifakwe kwi-solvent ngokupheleleyo.Umphezulu wetyhubhu yentsimbi awuvumelekanga ukuba uveze umphezulu wokunyibilikisa. Zide zombini iziphelo ityhubhu yentsimbi zingabi namaqamu, elinye icala lombhobho wentsimbi liya kunyuswa lihle lishukume, kwaye ityhubhu yentsimbi iya kunyuselwa lawula i-solvent ecocekileyo kwaye emva koko ungene kwibhentshi yokomisa.

2. I-Angle ethambekileyo yepayipi yensimbi ayiyi kuba ngaphezu kwe-15 ° kwinkqubo yonyango ye-solvent.

I-3, ityhubhu yentsimbi kwixesha lokuntywiliselwa kwe-solvent ye-60 ~ 120 imizuzwana, i-tube yokubuyisela i-3 ~ 5 imizuzu, ukucwiliswa kwe-tube yokubuyela kwi-5 ~ 10 imizuzu.

4. Iqondo lobushushu lokunyibilikisa: Gcina isinyibilikisi sicocekile kubushushu begumbi.

5. Emva konyango lwe-solvent, musa ukunamathela kolunye ukungcola, musa ukuba manzi, lubeke kwitafile yokomisa ukuze ulinganiswe; Abantu abavumelekanga ukuba banyathele kumbhobho wentsimbi obekwe kwibhentshi yokomisa.Ukuba kufuneka inyathelwe, iinyawo zombini kufuneka ziqatywe ngeammonium chloride phambi kokuba kusetyenzwe kumbhobho.1.Emva konyango olufanelekileyo lwe-solvent, beka ityhubhu yentsimbi kwiqonga lokomisa kunye nokwamkela, kwaye ubeke ityhubhu yentsimbi kwicala langaphambili lembiza ye-zinc kunye necala langaphambili le-roller yesibini yamagnetic ukuya kwisikwere kwi-Angle yasekunene; ngasemva okanye iqondiswe kwaye ibekwe kwi-rack yokufumana.

2. Umsebenzi oyintloko wokumisa i-KANG kukumisa amanzi phezu kombhobho wensimbi.Kwelinye icala, kukuphakamisa ubushushu bombhobho wentsimbi ngokwawo, ukuthintela ukutshiza kwe-zinc ekulimazeni abantu, kwaye ungasusi amandla obushushu kwimbiza ye-zinc, ukuze kukhawuleziswe ukubunjwa kwe-zinc-ferroalloy layer.

3. Ubushushu bokomisa kwe kang yi 80℃ ~ 180℃, kwaye ixesha lokumisa lombhobho wentsimbi yi-3 ~ 7 imizuzu.Ubushushu bokomisa bunokulawulwa ngokweenkcukacha kunye nobukhulu bodonga lombhobho wentsimbi.Izomisi kufuneka zijonge iqondo lokumisa lombhobho wentsimbi nangaliphi na ixesha ukuthintela ukungabikho kwexesha kwi-zinc liquid splash zinc ukulimala;Xa usomisa, yenza ungagqithisi kwiqondo lobushushu, ukuthintela i-coke yokubhaka enyibilikisiweyo. Umbhobho wentsimbi otshisiweyo wamkela umgaqo womatshini wokudayela ngaphakathi, ukucinezela, ukujikeleza, ukutsalwa ngaphandle kunye nokuphakamisa indlela yokudipha ngokupheleleyo umbhobho wentsimbi owenziwe ngamachiza ukuba ugqibezele. inkqubo ye-galvanizing yediphu eshushu.

1. Ukulawulwa kweeparamitha zenkqubo: Ubushushu besisombululo se-zinc kufuneka balawulwe phakathi kwe-440-460 ℃; Ixesha lokudipha i-Zinc kufuneka lilawulwe phakathi kwemizuzwana engama-30-60; Umxholo we-Aluminium (inqanaba lolwelo lweZinc equkethe i-aluminium 0.01-0.02%)

2. I-zinc ingot kufuneka ibe yi-zN0-3 ingot ye-zinc kunye nomgangatho wesizwe.

3. Gcina kwaye ulawule ukusebenza okuthembekileyo kokukhupha kunye nokucofa i-screw kunye nokukhupha isixhobo sokuphakamisa rhoqo, ukuqinisa i-lubrication ye-cylinder, ukulungelelanisa ukuphakama kunye ne-Angle ye-galvanizing pipe distributor kakuhle, kwaye ulungelelanise izixhobo kwindawo efanelekileyo.

4. Beka indawo yokutshintsha ngokuchanekileyo; Umgca we-thermocouple kunye nemitha isetyenziswe kwimodeli efanayo, ngaphandle koko, impazamo yobushushu inkulu, umkhono wokukhusela we-thermocouple, uhlala ukhangele kwaye utshintshe.

5. Umqhubi wesikhululo sokusebenza uya kulungelelanisa ngesandla isantya ngokwemeko yokusebenza kwesixhobo esiphambi kwesithando somlilo kunye nomyalelo wesenzo sokuthintela ukunamathela kombhobho.

6. Fudumeza izixhobo ezisetyenziswa ngabasebenzi beziko ngaphambi kokuba uzisebenzise ukunqanda ukuchitheka kwezinki nokwenzakala;Khangela rhoqo ukuba umbhobho wentsimbi uwela embizeni, ukuba ukhona, ukuze ucime kwangethuba; ukuqinisekisa ukhuseleko lwezixhobo.

7. Xa ufaka i-zinc kwibhodwe le-zinc, i-zinc ingots kufuneka ifudumale kuqala.Ungaze uvumele iinyanda ze-zinc ukuba zongezwe, akukho ngaphezu kwamaqhekeza amahlanu e-zinc ngexesha.Akuvunyelwe ukulahla isinyithi kwi-zinc liquid ukukhusela i-zinc slag eninzi.

I-8, xa i-zinc inyibilika kufuneka ifudunyezwe ngokukhawuleza, ungatshisi umlilo, ngaphandle koko iya konakalisa ubomi bembiza, kwaye kukho i-volatilization ye-zinc eninzi. ".Kwinkqubo yokunyibilikisa i-zinc, xa i-zinc inokushisa okuphezulu akufanele ithinte ibhloko ye-zinc ngesandla, ukuze ugweme ukutshisa, kufuneka isebenzise izixhobo ezifanelekileyo zokuyibamba.

9, ukucima rhoqo i-zinc ebusweni bolwelo lwe-zinc. ukudipha zinc okanye ngaphandle ityhubhu xa uqhagamshelwano ityhubhu yentsimbi, ukuze ungaqengqeleki phezu isenzeko iingozi zobuqu okanye iingozi izixhobo.

10. Iibhloko ze-zinc emhlabeni phambi kwesithando somlilo, i-zinc eyaphukileyo, i-zinc ekhutshwe xa i-galvanizing, kunye nombhobho wentsimbi ye-zinc ogeleza ngaphandle kufuneka uhlaziywe nanini na ukunciphisa ukulahleka kobushushu bembiza ye-zinc.

11. Xa ii-ingots ze-aluminium zongezwa kumphezulu we-zinc engamanzi, kufuneka ihanjiswe amaxesha amaninzi ngaphambi nangemva kokuqinisekisa umxholo we-aluminium ofanayo kumphezulu we-zinc engamanzi.

12. Ukuze kube lula ukukhukuliseka kwamanzi kunye nokutsalwa kwe-zinc, iitoni ezingama-20 zelothe kufuneka zifakwe ngaphakathi kwimbiza ye-zinc.

I-13, i-slag dregs yokutshisa i-dregs, i-zinc slag iya kwahlulwa ibe yibhloko enkulu kunye nencinci yokugcina iibhloko, ubushushu be-dregs kufuneka ilawulwe kwi-455 ℃ ngaphezulu, umatshini we-swing slag kufuneka usebenzise izixhobo ezikhethekileyo, kude ne-zinc pot 1 mitha, iinyawo zokuma kwimilo engu-t.

I-14, iimfuno zenkqubo yediphu eshushu ngqongqo ngakumbi, ngoko ke kwinkqubo yokuvelisa idiphu eshushu, kufuneka yome isikhululo esipheleleyo, oko kukuthi, kwinani leengcambu zexesha leyunithi okanye iitoni ezingaphezulu, iindleko ezisezantsi, kwaye ngokuphambeneyo ziphezulu.1.Emva kokuba umbhobho we-galvanized ubekwe phambili, itafile ye-magnetic roller isetyenziselwa ukukhokela umbhobho we-galvanized, kwaye ukuguqulwa komatshini ohamba phambili akukhawulezi kakhulu, ukwenzela ukuba i-zinc ihambe icocekile ngaphambi kokuvuthela kwangaphakathi.

2. I-Angle yendandatho yokuvuthela yangaphandle kufuneka ihambelane ne-roller magnetic kwii-angles ezichanekileyo, kunye neendawo zobude kunye neziguquguqukayo kufuneka zibe zilungile ukuqinisekisa ukuba umbhobho we-galvanized udlula embindini wendandatho yomoya.

3. Xa ufaka i-roller magnetic, i-roller magnetic emihlanu kufuneka ibe kumgca ophakathi ukuze kuqinisekiswe i-uniform zinc layer yombhobho ovuthelweyo wangaphandle.

4. Ukuvuthela kwangaphandle kuya kuqhutywa ngomoya ocinezelweyo, ngokukhethekileyo ngaphezu kwe-70℃, phantsi koxinzelelo lwe-0.2-0.4mpa.

5. Uxinzelelo lomoya luya kulungelelaniswa phantsi kwezi meko zilandelayo:

(1) Umaleko we-zinc kumphezulu ongaphandle wombhobho wegalvanized kakhulu.

(2) Umphezulu we-zinc layer uba mnyama emva kokuvuthela ngaphandle.

3Umthamo womoya kufuneka ulungelelaniswe.

6. Faka indawo yendandatho yomoya yenkcazo efanayo ngokwenkcazo yombhobho wensimbi.Umsesane womoya awukwazi ukutshintshwa ngezinye iinkcukacha.

7. Akuvunyelwe ukudlula umbhobho we-galvanized phantsi kwemeko yokungabikho moya, ukuze ungabangeli ukuvalelwa komngxuma womoya kwaye uthintele umgangatho wokuvuthela kwangaphandle.

8. Ngalo lonke ixesha khangela ukuba ngaba ngaphakathi kwiringi yokuvuthela yangaphandle kucocekile, ingaba kukho i-zinc ejingayo, ukuba umphandle wombhobho wegalvanized ugudile kwaye kukho ukukrwela; , ukuba kukho kudibaniswa ne-zinc ukucoca ngexesha.

9. Ekubeni ingekho i-roller magnetic kunye ne-zinc layer ayiqini, umphezulu we-zinc layer yeyona nto inokwenzeka ukuba ikrwelwe, ngoko ke isantya se-roller ehamba phambili kufuneka ihambelane kakuhle ne-roller magnetic.1.Umbhobho oshushu wediphu uthunyelwa kwicala lesivutheli sangaphakathi ngesixhobo esikhokelayo, kwaye iswitshi ekufutshane isetyenziselwa ukugqiba intshukumo ethe tye, cinezela ukuvuthela kwangaphakathi, ukuphakamisa intloko yoxinzelelo, kwaye ushukumise idiphu eshushu. umbhobho kwisinki yokupholisa.

2. Ityhubhu efakwe eshushu yeyona nto inokuthi ikrwelwe kwitafile yerola elikhokelayo.Isizathu esona sizathu kukuba i-zinc ayizange iqine ngokupheleleyo ngexesha lokusebenza kombhobho.

3. Umphunga usetyenziselwa ukuvuthela kwangaphakathi, kwaye uxinzelelo lokuvuthela lwangaphakathi yi-0.4-1.0mpa; Umphezulu wangaphakathi wombhobho wegalvanized kufuneka ube mpuluswa.

4, umbhobho zangasese kwikhonkco ukugcina iAngle ethambekileyo ethile, ukuze umnatha amanzi okupholisa.

5. Indawo yokusebenzela yokuvuthela kwangaphakathi ibekwe kwindawo engumnqantsa enendawo encinci yokusebenza, ngoko ke kufuneka iqhutywe ngononophelo ukuthintela ukutyibilika, ukuwa nokugoba ukwenzakala; ukuze aphephe ukwenzakala.

6. Nika ingqalelo ukuba iinyawo zakho zime ziqinile kwaye kukho eminye imiqobo ekuthintela ukuba ungaweli echibini;Kulula ukulishiya ityathanga libaleka kwi-sink, ukunqanda ukulimala kombhobho ophaphazelayo.Intsingiselo: Xa amalungu kufuneka agcinwe kunye nokuthuthwa ixesha elide, ukugqithisa kufuneka kuqhutywe phakathi kwamacandelo ukuthintela ukubola kwindlela yokugcina kunye nokuthutha.Imveliso ye-corrosion idla ngokubizwa ngokuba yi-white rust.Iindlela eziqhelekileyo zokudlula ziquka i-chromate kunye ne-phosphate.

1. Indlela yokuqhubela phambili: umbhobho otshisiweyo oshushu-dip usetyenziselwa ukutshiza isisombululo se-passivation ngqo kumgaqo weenqwelo-moya, kwaye isisombululo siyacinywa kumgama wemitha enye ukusuka kwindawo yokutshiza ngemela yomphunga.Qaphela ukuvuthela isisombululo se-passivation.

2. Sula ngomoya oxinyiweyo ukuze uvuthe i-liquid phezu kombhobho wensimbi kwaye wenze i-coating uniform.Ngokulungelelanisa uxinzelelo lokulungelelanisa ubukhulu bengubo, akukho buhlalu obugqithisileyo kufuneka bufakwe kumphezulu we-tube ye-zinc. 1.Uphawu lokuqengqeleka kunye nerola:

1) Xa umatshini wokumakisha usebenza, ungachukumisi i-roller yokumakisha ngesandla sakho ukuze uthintele ukucinezela isandla; Akuvumelekanga ukudlula umbhobho ophindwe kabini kumatshini wokumakisha ukukhusela umonakalo we-press roll.

2) Ngethuba lokusebenza kombhobho we-galvanized kwitafile yokuhambisa i-roller, umatshini wokumakisha uya kutshintsha inqaku ngokweenkcazo ezahlukeneyo, kwaye ukuphakama kwevili lokushicilela kuya kulungelelaniswa emva kokuba iinkcukacha zitshintshwe, kwaye ioli iya kudibaniswa rhoqo.

3) Iringi yerabha yomatshini wokumakisha kufuneka ihlolwe rhoqo kwaye ithathelwe indawo ngexesha ukuba kukho ukuqhekeka kufunyenwe.

I-4) Ivili le-rubber liya kucinezelwa kumgca ophakathi kwi-tube yensimbi, kwaye iibholiti eziphezulu kunye nezantsi zokulungisa i-Angle efanelekileyo iya kulungiswa.

5) Xa uprinta iringi yelogo, abantu ababini kufuneka baqengqe ngaxeshanye.I-inki kufuneka idityaniswe rhoqo ukuqengqeleka umbhobho wentsimbi ngefelti, kodwa i-inki ayilulanga ukuba kakhulu.

2. Ukupakishwa:

I-1) I-baler ISEBENZA igesi ye-compressor yomoya, kwaye uxinzelelo luyi-0.4-0.8mpa.Kunqatshelwe ukuba uthinte iindawo ezihambayo ze-baler ngezandla zakho ukuze ugweme ukulimaza izandla zakho phantsi kwemeko yokusebenza yebhali.

2) Xa upakisha, faka kuqala iibhanti kwibhanti yokupakisha, uze ubeke ibhande lokupakisha malunga nombhobho wensimbi kwaye ufake enye isiphelo kwiibhanti.Emva koko cinezela umatshini wokupakisha kwibhanti yokupakisha kwaye uvule i-valve yomoya yomatshini wokupakisha ukupakisha kunye nokucinezela.Inxalenye eninzi yebhanti yokupakisha yi-1.0-1.2mm.Ibhanti yokupakisha kufuneka ibe yi-100mm ukusuka ekupheleni, i-300mm kude nenxalenye yesibini, kunye ne-400mm ukusuka ekupheleni kophawu lwebha eluhlaza.

3) Khetha i-rack yokupakisha yenkcazo efanayo kwimibhobho ye-galvanized, faka imibhobho ye-galvanized kwi-hexagonal shape kwaye wenze isiphelo esinye.

4) Emva kokuba indawo yangaphandle yombhobho wentsimbi epakishweyo ibangela ungcoliseko, yicoce ngesanti ecocekileyo yomqhaphu ngaphambi kokupakishwa.Ukuba iimeko zivuma, amanzi angaphakathi kumbhobho omncinane kufuneka alawulwe kwaye acocwe;Musa ukuvumela nabani na ukuba anyathele ityhubhu ngonyawo lwakhe, ukugcina inkangeleko yomgangatho wetyhubhu yagalvanized.

I-Tianjin Rainbow Steel Group yimveliso yentsimbi yobuchwephesha eyenziwa eTshayina.

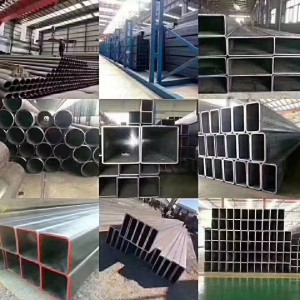

Imveliso sinokuyenza ngolu hlobo lungezantsi:

Uluhlu lwethu lweMveliso ePhambili:

1. Umbhobho wentsimbi(Umjikelezo / Isikwere/ Ekhethekileyo/SSAW)

2. Umbhobho woMbane woMbane(EMT/IMC/RMC/BS4568-1970/BS31-1940)

3. ICandelo leNsimbi eliBande(C /Z /U/ M)

4. I-Angle yentsimbi kunye ne-Beam( Ibha ye-engile ye-V / i-H Beam / i-U Beam)

5. Ipropu yeScaffolding yentsimbi

6. Ulwakhiwo lweNsimbi(Imisebenzi yesakhelo)

7. Inkqubo echanekileyo kwiNsimbi(ukusika, ukulungisa, ukucaba, ukucofa, ukuqengqeleka okushushu, ukuqengqeleka okubandayo, ukunyathela, ukugrumba, ukuwelda, njl.njl. Ngokwemfuno yomthengi)

8. Inqaba yentsimbi

9. Ulwakhiwo lokuNxulumana neSola

Uncedo lweNkampani yethu:

1.Ixabiso:Inkampani yethu iseTianjin China.Kangangamashumi eminyaka, iTianjin ibe liziko loshishino lwentsimbi kunye nesiseko esikhulu sokuvelisa umbhobho wentsimbi eTshayina.Ikhonkco loshishino lwentsimbi kunye neemveliso zetsimbi lugqityiwe;Inomathiriyeli omkhulu kunye nezibonelelo zabasebenzi apha.Ngoko iintlobo zemibhobho yensimbi ezenziwe apha ziphelele kakhulu, umgangatho uphezulu, ixabiso lincedo kakhulu.NJENGEnkampani yeqela, iifektri zethu ezine zinokufumana ixabiso elincomekayo lemathiriyeli ekrwada ngenxa yokuthenga okuninzi kwebhetshi enye yezinto.Amaxabiso eemveliso ezithunyelwa ngaphandle ngawo onke amaxabiso eqela le-intro-group, ngoko ke sinenzuzo yexabiso ngaphezu kwabanye abathengisi ngaphandle abazimeleyo.

2.Ezothutho:Izixhobo zethu zokusila zikumgama oziikhilomitha ezingama-70 kuphela ukusuka kwizibuko laseTianjin, elilelona zibuko likhulu kumantla eTshayina, kunye neenqanawa ezithunyelwa kumazibuko angaphezu kwama-300 kumazwe angama-170.Inkampani yethu kuphela Ilula kakhulu kwaye igcina zombini ixesha kunye neendleko zokuhamba.

3.Inkonzo yokumisa enye:Njengenkampani yeqela, sinezixhobo ezine zokusila ezinendawo yokugcina impahla kunye nendawo yokucubungula, sinokukubonelela ngoluhlu olubanzi lweemveliso zentsimbi: i-hot rolled kunye nebandayo eyenziwe, kubandakanywa uluhlu olubanzi lwebar yomthengisi, i-structural and tubular products.Sinazo zonke izinto zentsimbi zasekhaya, zorhwebo kunye nezoshishino kunye neenkonzo onokuthi uzifune.Ngoko ukuba uthenga kuthi, into esinokubonelela ngayo yinkonzo yemveliso yensimbi enye.Igcina ixesha lakho elininzi lokuthenga kunye neendleko zokukhangela.

4. Umthamo weMveliso kunye nokuhanjiswa:

Sinomthamo omkhulu wemveliso, kwaye sithumela ngaphandle kweetoni ezingaphezu kwama-3500 ngeveki (phantse i-150 20 yezikhongozeli ze-GP), sinokuhambisa iimpahla Ngeentsuku ezingama-20-30 emva kokufumana idiphozithi ye-T / T okanye i-L / C.Kwii-odolo ezikhethekileyo eziphuthumayo, sinokunciphisa ixesha elihamba phambili ukuya kwiintsuku ze-10.

5. Yenziwe ngokwemigangatho eyahlukeneyo, Dibana nemigangatho eyahlukeneyo:

Ekubeni iimveliso zethu zithunyelwe kumazwe amaninzi ahlukeneyo kunye nemimandla efana neYurophu, iMelika, i-Australia, i-Afrika, i-Asia njl.Ukuba uneemfuno ezikhethekileyo, sixelele nje, sinokukuvelisela iimveliso ezilungiselelwe wena, kungekuphela nje ukufezekisa iimfuno zakho zomgangatho, kodwa kwakhona ukonga iindleko ezininzi.

Abasebenzi bethu abanamava nabanolwazi bahlala bekulungele ukuphendula imibuzo yakho malunga neemveliso kunye neenkonzo zethu.

Tianjin Rainbow Steel Group Co., Ltd.

Umnxeba: 0086-22-59591037

Ifeksi: 0086-22-59591027

Iselula: 0086-13163118004

I-imeyile:tina@rainbowsteel.cn

Wechat: 547126390

Iwebhu:www.rainbowsteel.cn

Iwebhu:www.tjrainbowsteel.com

Ixesha lokuposa: Aug-17-2020