1.Iindleko zonyango eziphantsi: Iindleko zokugalela idiphu eshushu zingaphantsi kunezinye iipeyinti zokuhombisa.

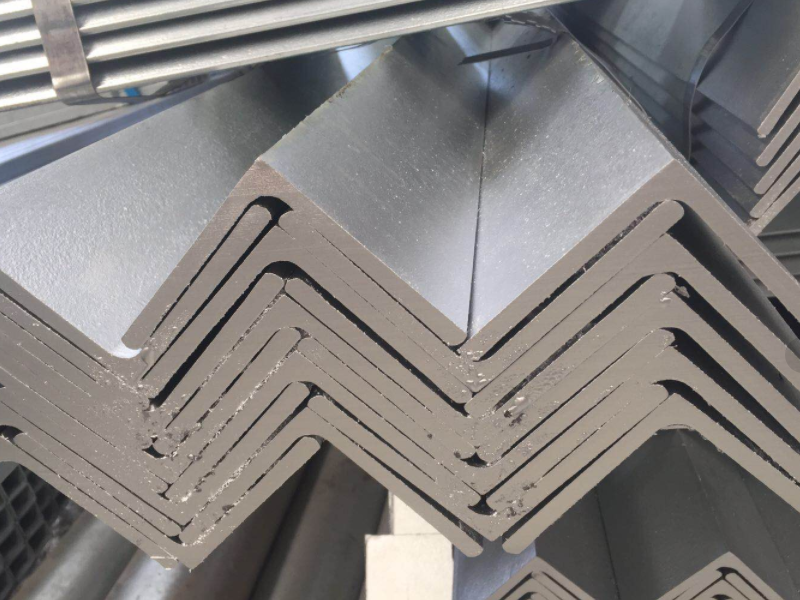

2.Yomelela: Idiphu eshushuintsimbi eyile yentsimbiineempawu zokucwebezela komphezulu, umaleko we-zinc ofanayo, akukho kuvuza, akukho ukutyibilika kwedriphu, ukuncamathela okuqinileyo kunye nokumelana nomhlwa okuqinileyo.Kwimo engqonge idolophu, ubungqingqwa obuqhelekileyo bediphu eshushu-ubungqina bokurusi bunokugcinwa ngaphezu kweminyaka engama-50 ngaphandle kokulungiswa;kwimimandla yasezidolophini okanye ekude nonxweme, ubungqingqwa obuqhelekileyo bomaleko obushushu owenziwe ngamazinki obungangenwa ngumhlwa bunokugcinwa iminyaka engama-20.Ayidingi kulungiswa.

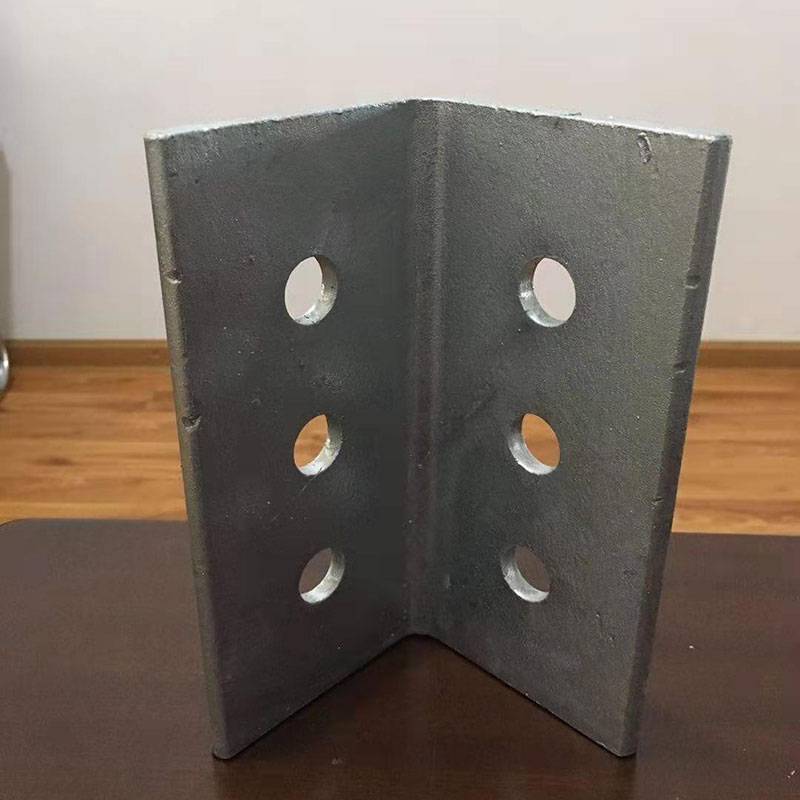

3.Ukuthembeka okulungileyo: I-galvanized layer yi-metallurgical bond kunye nentsimbi kwaye iba yinxalenye yentsimbi, ngoko ke ukuqina kwengubo kunokwethenjelwa ngakumbi.

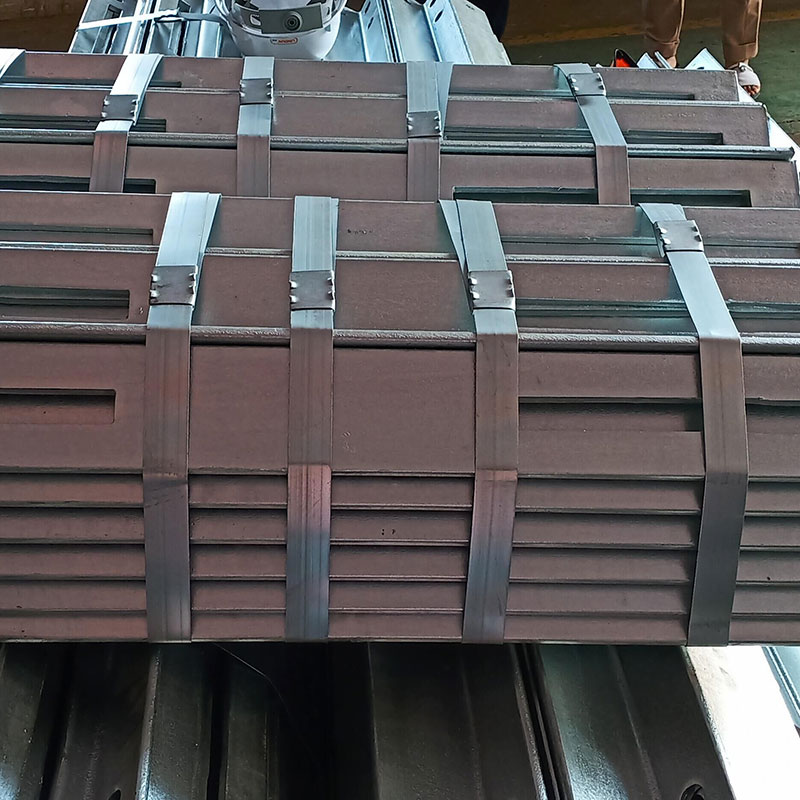

4.I-coating inobunzima obuqinileyo: i-galvanized layer yenza isakhiwo esikhethekileyo se-metallurgical, esinokumelana nomonakalo womatshini ngexesha lokuthutha kunye nokusetyenziswa.

5.Ukukhuselwa okubanzi: Yonke inxalenye yecandelo elicwengiweyo linokuthi lifakwe i-galvanized, nakwi-depression, ikona elibukhali kunye nendawo efihliweyo inokukhuselwa ngokupheleleyo;

6.Ukugcinwa kwexesha kunye nokugcinwa kwabasebenzi: inkqubo ye-galvanizing ikhawuleza kunezinye iindlela zokwakha iingubo, kwaye inokuphepha ixesha elifunekayo lokupenda kwisayithi emva kokufakwa.